Industry 4.0 has been a buzzword for more than a decade, but in 2025 it is no longer a promise it’s a reality. Smart factories, powered by automation, AI, and industrial IoT, are transforming global manufacturing into something faster, more adaptive, and more sustainable than ever before.

From Connected to Intelligent

Early smart factories were about sensors and connectivity. Today, the focus has shifted toward self-optimizing systems. Machines communicate, analyze data, and adjust production in real time. Digital twins simulate entire supply chains, while AI models predict equipment failures before they happen. The result: lower downtime, higher efficiency, and more agile operations.

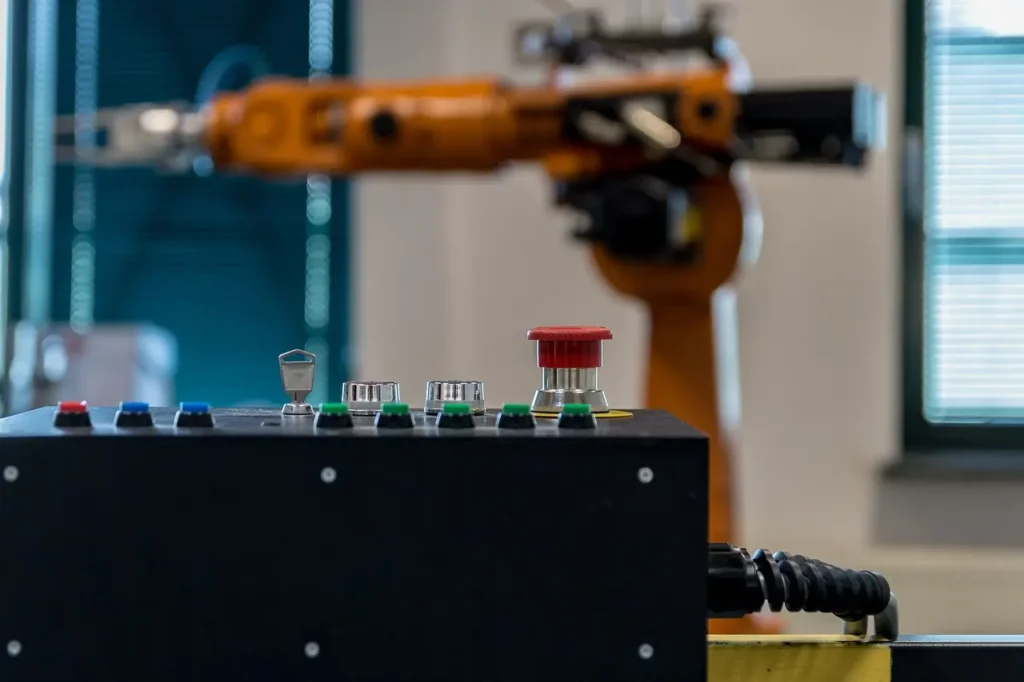

Automation as the Growth Engine

The industrial automation market, valued at over $220 billion in 2024, is projected to nearly double by 2034. Robotics, cobots, and autonomous systems are becoming standard on factory floors. Xiaomi’s “dark factory” in Changping, which produces a smartphone every second without human presence, illustrates how far automation has come and how quickly it is accelerating.

Human + Machine Collaboration

Despite the rise of autonomous systems, people remain central to Industry 4.0. Collaborative robots (cobots) are taking on repetitive tasks, allowing workers to focus on higher-value roles such as process optimization and data analysis. The challenge is reskilling: manufacturers need technicians who understand AI, data integration, and advanced automation systems.

Data: The New Factory Fuel

Automation succeeds only if the data behind it is clean, structured, and accessible. Too many manufacturers still struggle with fragmented legacy systems and data silos. Companies investing in edge-to-cloud integration, AI-driven analytics, and 5G connectivity are the ones unlocking real competitive advantages.

Sustainability Built In

Smart factories are increasingly designed with sustainability in mind. Florasis’s beauty factory in Hangzhou integrates its own “smart brain” system for end-to-end automation while running on solar power that generates 2.8 million kWh annually. Similar models are being adopted globally as manufacturers balance efficiency with environmental goals.

The Road Ahead

Looking forward, the future of smart factories will be shaped by:

- Hyper-automation: Autonomous production lines running 24/7 with minimal human oversight.

- Immersive technologies: AR and VR for real-time training, troubleshooting, and workflow guidance.

- Resilient supply chains: Digital twins and predictive analytics ensuring rapid response to disruptions.

- Secure connectivity: 5G, Wi-Fi 7, and edge security systems enabling real-time industrial intelligence.

Final Word

The future of manufacturing belongs to those who embrace automation not just as a tool, but as the backbone of an adaptive, data-driven enterprise. In 2025, Industry 4.0 is no longer about “preparing for change” it’s about building factories that learn, evolve, and compete in real time.