As factories, energy grids, and critical infrastructure accelerate their digital transformation, two skills have emerged as indispensable for engineers in 2025: PLC (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition).

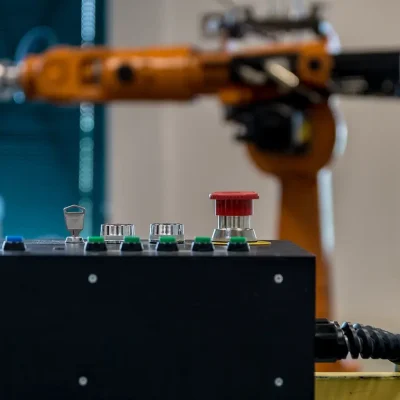

These technologies form the backbone of industrial automation. PLCs handle machine-level control, while SCADA systems provide real-time monitoring, visualization, and decision-making across entire plants. With Industry 4.0 now in full swing, demand for engineers who can master both is at an all-time high.

Why PLC Skills Are Vital

Programmable Logic Controllers (PLCs) remain the most reliable and flexible tools for controlling industrial equipment. From automotive assembly lines to water treatment plants, PLCs ensure precise, safe, and repeatable operations.

Why they’re in demand:

- Factories are increasingly upgrading to smart PLCs with integrated connectivity, cybersecurity, and remote programming capabilities.

- Engineers who can design, troubleshoot, and optimize PLC-based systems are critical to achieving efficiency and uptime.

- Knowledge of leading platforms like Siemens, Allen-Bradley, Mitsubishi, and Schneider Electric adds immediate value to employers.

The Role of SCADA in Industry 4.0

SCADA systems go beyond machine control to provide real-time monitoring, visualization, and remote management of operations. They are the “nerve centers” of modern industrial environments.

Why they’re in demand:

- Integration with IIoT sensors and AI-driven analytics enables predictive maintenance and process optimization.

- Cybersecure SCADA platforms are vital as factories and utilities face growing risks of cyberattacks.

- Energy, oil & gas, smart cities, and even renewable energy sectors rely heavily on SCADA engineers for system uptime and resilience.

Key Skills Engineers Need in 2025

To stay ahead, engineers must go beyond the basics. The most sought-after skills now include:

- Programming and Logic Design: Ladder logic, function block diagrams, and structured text.

- Networking & Protocols: Proficiency in Modbus, OPC UA, Profibus, and Ethernet/IP.

- Data Integration: Connecting PLC/SCADA with MES, ERP, and cloud platforms.

- Cybersecurity: Designing secure architectures for critical infrastructure.

- Simulation & Digital Twins: Using virtual models to test and optimize PLC/SCADA deployments before implementation.

Career Opportunities

Engineers with PLC and SCADA expertise are being hired across:

- Smart manufacturing: Automotive, electronics, consumer goods.

- Utilities & energy: Power grids, water treatment, renewable energy.

- Oil & gas: Pipeline and refinery monitoring.

- Infrastructure: Transportation, smart cities, and building automation.

Job roles range from Automation Engineer and Controls Engineer to SCADA Specialist and Industrial IoT Architect. Salaries are rising accordingly, with automation engineers commanding premium packages worldwide.

Final Word

In 2025, PLC and SCADA are no longer niche skills they are core competencies for engineers driving Industry 4.0. Those who master both programming and system integration will not only stay relevant but also lead the next wave of industrial innovation.

The future belongs to engineers who can connect machines, people, and data into one seamless ecosystem and PLC & SCADA expertise is the entry point to that future.