Industrial training has traditionally relied on manuals, classroom sessions, and on-the-job shadowing. While these methods have worked, they often struggle with high costs, safety risks, and inconsistent results. In 2025, Virtual Reality (VR) is transforming the way workers learn and prepare for complex industrial environments delivering immersive, safe, and scalable training solutions.

Safe Training for High-Risk Environments

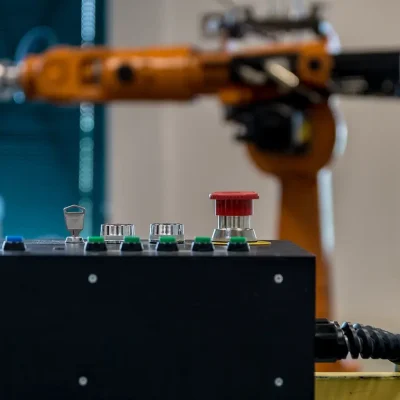

Industries like oil & gas, mining, aviation, and manufacturing involve hazardous processes where mistakes can be costly or dangerous. VR allows trainees to experience these scenarios in a controlled, risk-free environment.

- Workers can practice responding to chemical spills, machine malfunctions, or emergency shutdowns without real-world consequences.

- Repeated exposure builds confidence and reduces the likelihood of accidents once they step onto the factory floor.

Faster Skill Acquisition and Retention

VR-based training engages multiple senses, leading to higher knowledge retention compared to traditional classroom learning.

- Studies show learners remember up to 75% of information through immersive experiences, compared to just 10% from reading.

- Complex tasks such as operating CNC machines or configuring robotic arms can be repeated until mastered, without tying up valuable production equipment.

Reducing Costs and Downtime

Traditional training often means taking machinery offline or dedicating senior staff to mentorship. VR cuts those costs.

- Equipment stays in production while trainees learn virtually.

- Simulations can be reused, updated, and scaled across multiple sites.

- Travel and logistics costs for centralized training programs are dramatically reduced.

Personalized and Scalable Learning

Every trainee learns at a different pace. VR platforms capture real-time performance data reaction times, decision accuracy, error frequency allowing for tailored feedback and adaptive learning paths.

- Companies can standardize training across global sites, ensuring consistency.

- Updates to safety protocols or machine processes can be pushed instantly to all VR training modules.

Preparing for Industry 4.0 Workforces

As smart factories adopt robotics, AI, and connected systems, the skill demands on workers are shifting. VR makes it possible to upskill employees quickly in:

- Machine operation and troubleshooting

- Cyber-physical systems and digital twins

- Human-robot collaboration safety protocols

- Emergency response in automated environments

Final Word

VR is no longer a novelty in gaming it’s becoming a cornerstone of industrial training. By combining safety, efficiency, and scalability, VR is helping organizations prepare their workforce for the complexity of Industry 4.0.

In 2025, companies that invest in VR training aren’t just cutting costs they’re building more capable, confident, and future-ready teams.