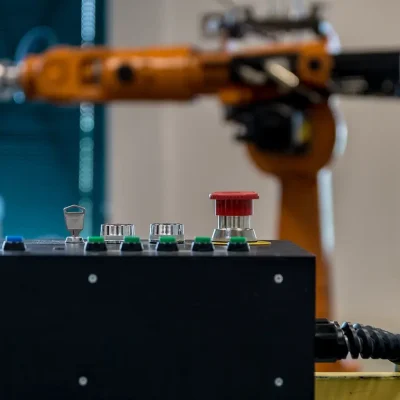

Industrial automation is advancing faster than the workforce can keep up. From smart factories to AI-driven production lines, the demand for automation engineers, PLC/SCADA specialists, robotics technicians, and data-savvy operators has never been higher. Yet companies worldwide are facing the same challenge: a widening skills gap that threatens productivity, innovation, and competitiveness.

How can organizations bridge this gap in 2025?

Why the Skills Gap Exists

Several factors contribute to the shortage of skilled professionals in automation:

- Rapid technological change: AI, IoT, robotics, and digital twins evolve faster than traditional training programs.

- Aging workforce: Experienced engineers are retiring, leaving fewer mentors for younger talent.

- Limited academic alignment: University curricula often lag behind industry needs, focusing on theory over hands-on automation skills.

- Global competition: Talent is scarce and highly sought after across manufacturing, energy, logistics, and infrastructure.

Key Skills in High Demand

Employers are searching for candidates who can combine traditional engineering with digital fluency:

- PLC and SCADA programming and troubleshooting

- Robotics and cobot integration

- Industrial networking and communication protocols (OPC UA, Modbus, Ethernet/IP)

- Predictive maintenance and data analytics

- Cybersecurity for industrial control systems

- Integration of automation with MES, ERP, and cloud platforms

Strategies to Close the Gap

1. Industry Academia Partnerships

Companies can work with universities and technical institutes to update curricula, offer internships, and provide access to real automation systems rather than outdated labs.

2. Reskilling the Existing Workforce

Upskilling technicians and operators through structured training programs, VR simulations, and certifications ensures companies don’t lose productivity while recruiting new talent.

3. Apprenticeships and On-the-Job Learning

Hands-on programs allow recruits to gain practical experience in automation environments something classroom training alone cannot provide.

4. Attracting Younger Talent

Positioning industrial automation as cutting-edge and impactful not “old factory work” can draw in Gen Z engineers who value technology and innovation. Highlighting sustainability and smart manufacturing also resonates strongly with younger professionals.

5. Global and Remote Talent Pools

In a digital-first world, organizations can tap into global expertise, using remote monitoring, cloud platforms, and virtual collaboration to fill skill shortages locally.

The Role of Emerging Technologies

New training tools like VR/AR for industrial training, AI-powered coaching, and digital twins make it easier to accelerate learning curves. By blending traditional engineering with these new platforms, companies can shorten the time it takes to build job-ready automation professionals.

Final Word

Bridging the skills gap in industrial automation isn’t just about hiring faster—it’s about creating a sustainable talent pipeline. Companies that invest in training, partnerships, and workforce transformation will be the ones that thrive in Industry 4.0.

In 2025, the winning strategy is clear: build talent, don’t just chase it.