Manufacturing is responsible for a significant share of global carbon emissions. As industries worldwide commit to net-zero targets, the question is no longer if factories will change, but how. One of the most powerful enablers in this transformation is automation.

By making operations smarter, leaner, and more efficient, automation is helping manufacturers cut waste, reduce energy use, and move closer to sustainable, net-zero production.

1. Energy Optimization Through Smart Systems

Automated systems equipped with sensors, AI, and predictive analytics allow manufacturers to monitor and adjust energy use in real time.

- Smart controllers optimize HVAC, lighting, and machine operations to prevent energy waste.

- Automated shutdown protocols ensure idle equipment doesn’t consume unnecessary power.

- Data-driven insights help shift production schedules to align with renewable energy availability.

2. Reducing Material Waste

Automation enhances precision in production, minimizing errors and reducing scrap rates.

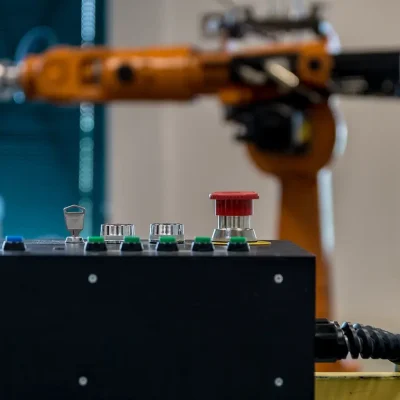

- Robotics and CNC machines deliver consistent accuracy.

- AI-powered quality checks identify defects early, preventing wasted materials.

- Digital twins simulate production processes to optimize material flows before physical trials.

3. Enabling Circular Manufacturing

Automation supports the transition from a linear “take-make-dispose” model to a circular economy.

- Automated disassembly systems make it easier to recycle or repurpose components.

- Smart sorting robots improve recycling efficiency by separating materials at high speed.

- Integrated tracking systems ensure resources are reused instead of discarded.

4. Supporting Renewable Energy Integration

Automated energy management platforms allow factories to integrate renewable sources like solar and wind into their operations.

- Smart grids balance loads between renewables and traditional sources.

- Battery storage systems can be automated to charge and discharge at optimal times.

- Factories can automatically adjust production intensity based on energy availability.

5. Data-Driven Sustainability Decisions

Industrial IoT devices and automation platforms generate actionable data that guides sustainability initiatives.

- Carbon footprint tracking per product or batch.

- Lifecycle analysis of raw materials and energy usage.

- Automated compliance reporting for environmental regulations.

Final Word

Automation is no longer just about efficiency it’s about sustainability. By reducing energy consumption, minimizing waste, enabling circular practices, and integrating renewables, automation is a cornerstone of net-zero manufacturing strategies.

In the race to meet climate goals, manufacturers that embed automation into their sustainability roadmap will gain not only regulatory compliance but also competitive advantage in a greener economy.